Did you ever wonder what happens to things of old metal that people use and throw away? Actually, nearly all metal is recyclable and can be reprocessed into both new raw materials and products. One way to achieve this is using a piece of equipment known as steel briquetting press. This machine enables us to convert junk metals into quality resources with a lot of potential life.

The Steel briquetting press is a type of machinery uses stiff metal scrap to produce small, large weighted surface blocks. These briquettes are sold to factories and other places where they can be used for the manufacture of new metal products. In doing so, we protect the amount of rubbish at landfills and save important natural resources. Making new metal from recycled materials is also less expensive and requires less energy to extract it directly from the earth. So we get to help the environment while making some savings!

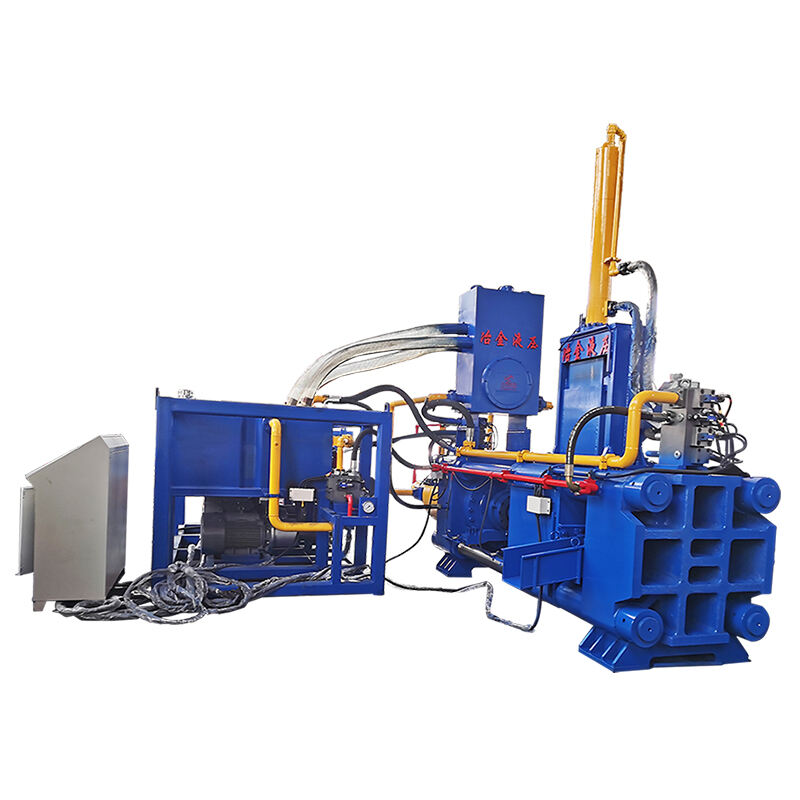

Steel briquetting presses are better for the environment and easier to work with. The tiny machine, which operates on electricity and makes use of pressure to cut metal refuse into dense pucks. That sounds a heck of lot easier than going at it with cutters to try and recycle the metal. The steel briquetting press can help you recycle most of the metal waste quickly, which is really crucial.

The good news is that these machines are better for the planet too. They reduce waste which would be thrown away and save the natural resources we depend on. When we recycle metal, so more are not pulled out of the ground which can hurt the planet and a lot less energy is used to make things from zero. And this is how we can make life easy for everyone by making the planet cleaner and safer.

Factories can receive more money than selling loosing metal waste, if they sell their metallic as briquettes. That is why briquettes are also in high demand by foundries and other factories which require equitements for heavy works. Steel waste is compressed into briquettes at the factory, which in larger amounts can be sold for money to improve their production with new machines and technology.

How is the steel briquetting press produced from how many types of it? Others are built for small factories, others can process the metal waste of a metropolis. While these steel briquetting presses may be of varying sizes, they all are durable and reliable units able to quickly convert shredded materials into compact-sized, easy-to-carry bales.

The steel briquetting presses are made of high-quality materials and have a long service life. They are built to last, with plenty of heavy lifting capacity and high-quality materials that can withstand hard use. Some steel briquetting presses are so advanced that they even offer automatic features. This also makes it so workers have to worry less about being near the machine and more on other things.

We provide a wide range of hydraulic machines such as hydraulic pressing presses for briquetting hydraulic balers and hydraulic alligator shears Our equipment is designed to be used in diverse applications across different industries such as steel briquetting press the automotive industry construction energy generation scrap recycling of metal Our equipment is suitable for many industrial applications due to its versatility

In Jiangyin Metallurgy Hydraulic Machinery Factory Our customers' satisfaction is our main goal. We offer steel briquetting press and customized solutions that meet the unique demands of our clients. Our after-sales staff is ready to help, whether you have questions about the equipment's operation or need assistance with troubleshooting. From purchase to installation We are committed to giving a seamless and effective service to our customers.

steel briquetting press founded in 1989 is a company with more than 30 years of experience in the field of hydraulics We are well-known within the domestic scrap metal recycling business for our long-standing experience and continuous growth We have been able to expand our market reach to more than 30 countries which includes Russia Brazil and Japan reflecting our leadership and trustworthiness in the business

Our two state-of-the-art plants that span steel briquetting press are equipped with cutting-edge technology and are staffed by a committed team of more than 150 professionals comprising 17 experts We pride ourselves on our outstanding capabilities in research and development evidenced by the 12 national patents we hold Our commitment to innovation guarantees that we always provide high-quality and effective hydraulic machinery solutions

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy