Ein Metall-Presswerk ist ein Mittel, um die Ressourcen eines Unternehmens durch die Umwandlung des begehrten Materials, Metallschrott, in Form von Metallpulver in einen festen Gegenstand zu konzentrieren. Die Maschine erreicht dies, indem sie dieses XXX-Material mit der Hand in Form fester Blöcke komprimiert, die als halb-einfache dichte Klumpen oder Presslinge bekannt sind. Diese Presslinge an Orte zu verkaufen, die sie recyceln, oder sie zum Wiederverwenden in neuen Produkten einzuschmelzen, bringt nicht nur Unternehmen Vorteile, sondern ist auch sehr umweltfreundlich, da es Abfall reduziert.

Wenn Sie ein Unternehmen sind, das Metalle in seiner Arbeit verwendet, gibt es Situationen, in denen kleine Metallstücke, die nicht mehr genutzt werden können, herumliegen. Sie versuchen, diesen Schrott loszuwerden, was kostspielig ist und noch mehr Platz in ihrem Bereich beansprucht. Eine Metall-Pressanlage ist die Lösung für Unternehmen wie folgt: Metallklippenschnürmaschine, Schnürmaschine für Abfallstahlspäne – Verkauf von Spaltschnürmaschinen, um diesen Abfall in etwas Nützliches umzuwandeln, das sie verkaufen können.

Das Brikettieren von Metallschrott macht es einfacher, sie zu lagern und zu transportieren. Dadurch wird Platz an ihren Arbeitsplätzen eingespart und es reduziert auch die Kosten für die Entsorgung. Außerdem können Sie einen Bonus erhalten, wenn Sie die Briketts an Recyclingzentren verkaufen. Nicht nur, dass dies ihre Gewinnmargen verbessert, es bietet auch eine nachhaltigere Arbeitsmethode.

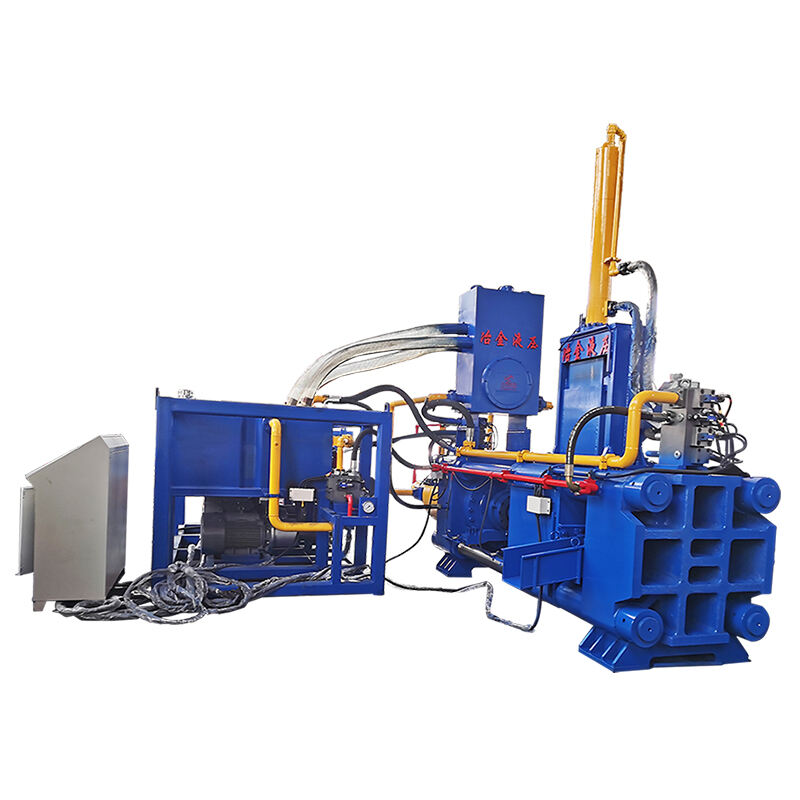

Der Fülltrichter ist der Punkt, an dem Metallschrott in dieser Maschine eingegeben wird. Wenn das Material drin ist, fließt es durch eine Form, die es zu einem Kuchen zusammenpresst, der als Pressling bekannt ist. Wenn der Pressvorgang abgeschlossen ist, kommt ein fertiger Pressling aus der Maschine und kann zum Lagern oder Verkauf für die Recyclingnutzung vorbereitet werden. Der gesamte Prozess ist außerdem umweltfreundlich und recycelt Abfallmaterialien.

Es gibt viele Gründe, eine Metallpressanlage zu verwenden, und diese Vorteile können Unternehmen Millionen von Geld sparen. Sie dient als wichtige Rettungsleine für Unternehmen, um das Volumen von Schrottmetall zu reduzieren, das einfach herumliegt. Firmen können diese Methode nutzen, um weniger Platz in ihren Anlagen einzunehmen, indem sie Presslinge herstellen, die den Metallschrott komprimieren, was Kosten für die Entsorgung reduziert.

Metallpressen sind ein wesentlicher, wertsteigernder und ertragsgenerierender Sektor im Metallrecyclinggeschäft, da sie es einfacher machen, Schrott zu verwalten. Der erste Schritt ist, so viel Metallschrott wie möglich zu sammeln. Eine Möglichkeit dazu ist, einen Prozess zu definieren, bei dem Sie Schrottmaterial von verschiedenen Maschinen und Stationen einsammeln, um auf Null-Ausfall zu kommen.

Sobald die Presslinge hergestellt wurden, verkaufen Unternehmen sie schnell an Entsorgungsstätten. Sie können die Presslinge auch direkt an diese Einrichtungen verkaufen oder einen Makler beauftragen, Käufer zu finden. Unternehmen sollten daher stets nach neuen Preisen für jedes Produkt suchen, da der beste Preis ihnen mehr Geld einbringt.

Die Jiangyin Metallurgy Hydraulic Machinery Factory, die im Bereich der Metall-Brikettierpresse gegründet wurde, verfügt über mehr als 30 Jahre Erfahrung in der Hydraulikbranche. Unsere langjährige Expertise und stetiges Wachstum haben uns zu einem führenden Namen in der heimischen Schrott-Recycling-Branche für Metalle gemacht. Unsere Marktposition erstreckt sich mittlerweile auf über 30 Länder, darunter Russland, Brasilien und Japan – ein Beleg für unsere Führungsrolle und Zuverlässigkeit im Geschäft.

Zwei unserer hochmodernen Einrichtungen mit einer Gesamtfläche von 30 000 Quadratmetern sind mit der neuesten Technologie ausgestattet und werden von einem engagierten Team von über 17 Metallbrikettierpressen-Experten betrieben. Wir sind stolz auf unsere hervorragenden Fähigkeiten in Forschung und Entwicklung, was durch die 12 nationalen Patente belegt wird, die wir besitzen. Unsere Leidenschaft für Innovation ermöglicht es uns, kontinuierlich qualitativ hochwertige und effiziente hydraulische Ausrüstung anzubieten

Bei der Jiangyin Metallurgy Hydraulic Machinery Factory steht die Kundenzufriedenheit im Mittelpunkt unserer Metall-Brikettierpressen. Wir bieten flexible und maßgeschneiderte Lösungen an, um die spezifischen Anforderungen unserer Kunden zu erfüllen. Unser Team aus After-Sales-Fachleuten steht stets zur Verfügung, um Unterstützung zu leisten – sei es bei Fragen zum Betrieb der Anlagen oder bei der Fehlerbehebung. Wir setzen uns dafür ein, unseren Kunden von der Bestellung über die Installation hinaus die reibungsloseste und effizienteste Erfahrung zu bieten.

Wir bieten eine breite Palette hydraulischer Maschinen an, darunter Hydraulikpressen zur Brikettierung, hydraulische Metallballenpressen und hydraulische Alligator-Scheren. Unsere Produkte sind für den Einsatz in zahlreichen Metallbrikettierpressen in verschiedenen Branchen konzipiert, darunter Stahlwerke, Gießereien, der Automobilsektor, der Bauwesenbereich, die Energieerzeugung sowie das Recycling von Altmetall. Diese Vielseitigkeit macht unsere Anlagen zur idealen Lösung für eine breite Palette industrieller Anforderungen.

Copyright © Jiangyin Metallurgie Hydraulikmaschinenfabrik Alle Rechte vorbehalten | Blog|Datenschutzrichtlinie