To many people, steel turnings may look like simple pieces of metal waste, but they are extremely useful in foundries. Steel turnings are used to create new items in foundries, so they need to be looked after very well. Enter the steel turnings compactor!

What Is a Steel Turnings Compactor?

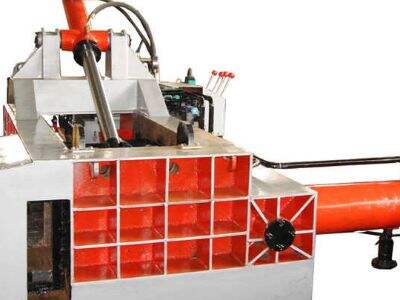

Steel turnings compactor is a big industrial machine that is used to process steel turnings in such a manner that a foundry can easily deal with their steel turnings. Foundries can avoid having to leave the turnings around, taking up room, by using a compactor to turn them into smaller shapes. This is to reduce labor inputs and costs to the foundry, making it easier to store and transport the steel turnings.

Advantages of using a Steel Turnings Compactor

Good points in using a steel turnings compactor in a foundry. First, it reduces the volume of scrap that the foundry has to store, as it minimizes the size of the resulting steel turnings. This allows the foundry to consolidate more turnings into less space, making room for all the other important stuff. Even more, railroad cars are more cost-effective to transport, which can help the foundry save dollars spent on shipping costs.

How Does the Compactor Facilitate Organization?

Handling metal cutting machine in a foundry can be a sizeable task, but a steel turnings compactor makes the job far simpler. The compactor ensures a tidy and organized workstation by compressing steel turnings! That also makes it safer for workers to handle the turnings, which reduces the amount of spills or accidents. Overall, one type of foundry processing line that keeps production flowing with ease is a steel turnings compactor.

Why Is Safety Important?

Steel turnings can be sharp, so they need to be handled with care. A steel turnings compactor crushes the turnings into smaller shapes, which makes them safer for workers. This excuses workers to seize and express the turnings without injuring themselves. It also prevents the turnings from damaging equipment or interfering with other jobs in the foundry.

How Does Recycling Help?

Recycling brick made machine warms our hearts, but foundries recycle steel turnings. Recycling scrap metal can be made easier by using a steel turnings compactor at a foundry. Parcel turnings occupy less space in recycling bins and have fewer overload on trucks that transport them to recycling centers. Of course, this minimizes waste and is aiding an environmentally friendly foundry industry.

To sum up, a steel turnings compactor is an effective solution for the foundry who wants to minimize their scrap production. A compactor saves foundries space, time, and money by pulverizing steel turnings into smaller formations. It also maintains the workspace, clean, organized, and safe for workers. Early on, a steel turnings compactor is an essential tool for enhancing the management of scrap and the recycling process at foundries.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

AZ

AZ

LA

LA

UZ

UZ