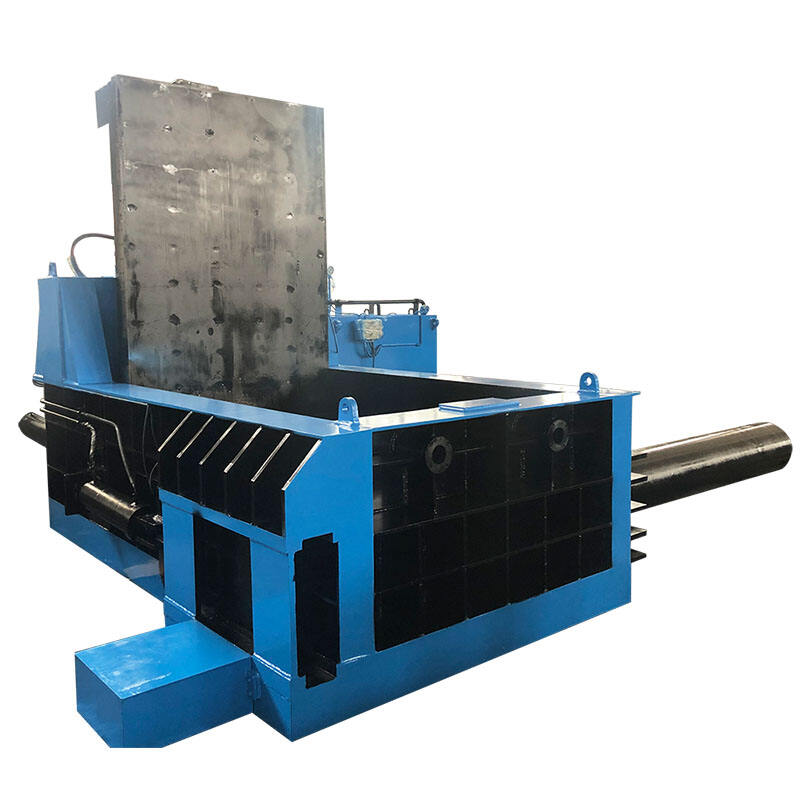

ماكينة ضغط فضلات الصلب: باعتبارها نوعًا من الماكينات الخاصة، تُستخدم ماكينة ضغط فضلات الصلب على نطاق واسع من قبل شركات إعادة التدوير. حيث تقوم بضغط الصلب القديم - وهو عبارة عن معدن زائد يأتي من مجموعة متنوعة من المصادر - إلى حزم كثيفة. هذا يجعل هذه الحزم أسهل في النقل والتخزين. تعبئة الصلب في حزم يجعل من السهل التعامل معه وإعادة تدويره، وهذه البنية التحتية تعد أساسية لشركات إعادة التدوير.

هناك الكثير من شركات إعادة التدوير وهم بحاجة إلى معدات تتعامل مع كميات كبيرة من الفولاذ الخردة بسرعة ودقة. هنا، يكون جهاز ضغط خردة الفولاذ موضع ترحيب كبير! هذا هو نوع من الماكينات الكبيرة التي ستحول تلك الأكوام الكبيرة من خردة الفولاذ إلى حزم مضغوطة بإحكام في وقت قصير. خردة الفولاذ المفردة تستهلك الكثير من المساحة بينما هذه الحزم تستهلك مساحة قليلة، مما يجعلها أكثر راحة. هذا أيضًا السبب في أن تكلفة نقل هذه الحزم أقل. بمجرد أن يتم ضغط الفولاذ، يصبح نقله أسهل إذا تم إرساله إلى مواقع أخرى لإعادة التدوير أو التخزين.

تلك الفضلات المعدنية ليست قمامة، بل مورد ذو قيمة! العديد من الأشياء يمكن إعادة تدويرها، حيث يمكن كسرها واستخدامها مرة أخرى لصنع منتجات جديدة. ومع ذلك، عندما لا يتم ضغط الفضلات المعدنية بشكل صحيح، يمكن أن تكون ضخمة ومزعجة لأنها تستهلك كميات كبيرة من المساحة مما يجعل نقلها على الشاطئ مستحيلاً. هنا يأتي دور ماكينة الضغط بفعالية! يتم ضغط الفضلات المعدنية بإحكام وتحويلها إلى حزم، مما يجعل تخزينها في مكان صغير أو حتى نقلها أسهل. ليس فقط يوفر هذا المساحة الثمينة، ولكنه يعني أيضًا أن الشركات تحصل على المزيد من المال عند بيع المعدن. كلما كانت الفضلات المعدنية أكثر جاذبية عند وضعها في حزم، يمكن أن تعطي عائدًا أفضل للشركة التي تبيعها للتدوير.

من الضروري الحفاظ على مكان عمل مرتب ومنظمة جيداً لأي شركة تدوير. استخدام ماكينة ضغط الفضلات المعدنية يمكن أن يبقي غرفة التدوير نظيفة ومنظمة. البالات الناتجة سهلة النقل والترتيب باستخدام هذه الماكينة. هذا يعني وجود كمية أقل من المعادن المُستعملة على الأرض، مما يحسن المظهر والأمان. بالإضافة إلى ذلك، عن طريق الحفاظ على بيئة عمل نظيفة يستطيع الموظفون العمل بشكل أسرع وتقل احتمالية وقوع الحوادث. المكتب مرتب ومنظم بحيث يسهل العثور على ما تحتاجه دون عناء، مما يزيد من سرعة العمل.

إذا كنت تمتلك كمية كبيرة من الفولاذ الخردة التي تحتاج إلى التخلص منها أو صيانتها أو إزالتها، فقد يكون ذلك مكلفًا للغاية ويستهلك الكثير من الوقت. وإذا كانت الفولاذ الخردة غير مرتبة، يمكن أن ترتفع تكاليف الشركة في العمالة والنقل بشكل كبير. ومع ذلك، فإن جهاز ضغط الفولاذ الخردة يمكنه توفير المال ببساطة عن طريق ضغط الحزم الصغيرة التي يمكنك نقلها بسهولة. يتم نقل هذه الحزم بشكل أسرع، ويحتاج الأمر إلى جهد أقل. وهذا يسرّع عملية إعادة التدوير بالكامل. بالإضافة إلى أن الشركات عندما توفر المال على التعاملات والشحنات، يمكنها استثمار المزيد في عملها - مما يمكّنها من النمو بشكل أسرع وأكبر وتحسين عمليات إعادة التدوير.

ستحقق شركات إعادة التدوير أرباحًا أكبر من خلال استخدام ماكينة ضغط فضلات الصلب ذات الجودة العالية. تترك حزم فضلات الصلب أثرًا أقل بعد أن تقوم ماكينة الضغط بضغطها، مما يجعلها أسهل في الإدارة وأسهل للبيع. لأن بيع المزيد من حزم فضلات الصلب يؤدي إلى تحقيق أرباح أعلى للشركات. كلما زادت الأرباح التي تحققها الشركة، استطاعت توفير معدات وعمليات أفضل لإعادة استخدام المواد بشكل أكثر فعالية. وهذا يخلق دورة فضلى من تحسين ونمو الشركة.

نقدّم مجموعة واسعة من الآلات الهيدروليكية، مثل آلات الضغط الهيدروليكية لتصنيع الكريات (Briquetting)، والماكينات الهيدروليكية لربط الخردة (Hydraulic Balers)، ومقصات التمساح الهيدروليكية (Hydraulic Alligator Shears). وقد صُمّمت معداتنا للاستخدام في تطبيقات متنوعة عبر قطاعات صناعية مختلفة، مثل ماكينات ربط خردة الفولاذ (Scrap Steel Baler)، وصناعة السيارات، والبناء، وتوليد الطاقة، وإعادة تدوير الخردة المعدنية. وتنبع ملاءمة معداتنا للعديد من التطبيقات الصناعية من مرونتها العالية.

مصنع جيانغين لآلات المعادن الهيدروليكية، الذي تأسس عام ١٩٨٩، هو شركة تمتلك خبرة تزيد على ٣٠ عامًا في مجال الآلات الهيدروليكية. وقد أثمرت خبرتنا العميقة والمستمرة في النمو عن بناء علامة تجارية رائدة في قطاع إعادة تدوير الخردة المعدنية. وتمكّنا من توسيع حضورنا في أكثر من سوق لآلات ربط خردة الفولاذ (Scrap Steel Baler)، بما في ذلك روسيا والبرازيل واليابان، وهو ما يدلّ على قوتنا ومصداقيتنا في هذا المجال.

مصنعانا الحديثان، اللذان يغطيان مساحة 30,000 متر مربع، مزودان بأحدث التقنيات لمكابس خردة الصلب. يتم دعمهما بفريق من 150 محترفًا، منهم 17 خبيرًا. نحن فخورون بقدراتنا القوية في البحث والتطوير، والتي تظهر من خلال حصولنا على 12 براءة اختراع وطنية. هذا الالتزام بالابتكار يضمن استمرارنا في تقديم حلول آلات هيدروليكية ذات جودة عالية وكفاءة.

في مصنع جيانغ يين لمachinery الهيدروليكية للمعادن، يعتبر ضاغط فضلات الصلب أولوية قصوى لدينا. نقدم حلول مرنة ومخصصة لتلبية الاحتياجات الخاصة لعملائنا. فريق الدعم بعد البيع متاح دائمًا لتقديم المساعدة سواء كان ذلك بالإجابة عن الأسئلة المتعلقة بتشغيل المعدات أو تقديم المساعدة في حل المشكلات. من الشراء إلى التركيب، يلتزم فريقنا بتقديم تجربة سلسة وفعالة لعملائنا.

حقوق النشر © مصنع جيانغين ميتالوجي هيدروليك ماشينيري جميع الحقوق محفوظة | المدونة|سياسة الخصوصية