Hello! Spotlight for today: A steel turnings briquetting press Thoughts, Ever Heard of That Machine It is quite interesting! It helps in converting scraps of metal (Metal chips and shavings) from different machines, which have been spent to provide a more useful purpose. The leftover pieces of the bar are called steel turnings. In workshops and factories, they can become a real headache as you lose an area of valuable floor space; any obstruction also constitutes an obvious trip hazard. This is the need of time for what briquetting press would your help out. These are very easy to store and transport as they compress the steel turnings into small, tight burbles of briquettes.

Provides Space: The amount of space in the workshop or factory can be occupied by steel turnings because it is large.ComponentPlacement On the right, briquettes are typically quite small and light in weight compared to their size; they can stack well as a result! This saves a huge amount of space in the workshop or warehouse, where they are housed.

Enhancing Safety: The continuing existence of sizeable piles steel turnings is not merely a danger to nearby workers. Briquettes are also very clean-packages and paving work accidents in the placeromium. This comes in handy and make not just the system, bit every one else safer.

Enviromental Benefits: Using a steel turnings briquetting press meanwhile, it is an environmentally friendly recycling equipment that can reduce waste and facilitate the reuse of recycled materials. This is relevant to the planet that sustains and makes Earth healthy.

Initiate the Machine: The machine can be started now that you have put your turnings into it. However, later the press would be used to compress into briquettes with high pressure. And that is what changes the loose pieces into solid blocks!

Turning also includes a form of recycling, with metal turnings briquetting pressIf you believe that all humans need to do their part conserving the environment.Logging is one such activity where practises are constantly being reviewed. Some of the ways in which it can help spill over to sustainability are:

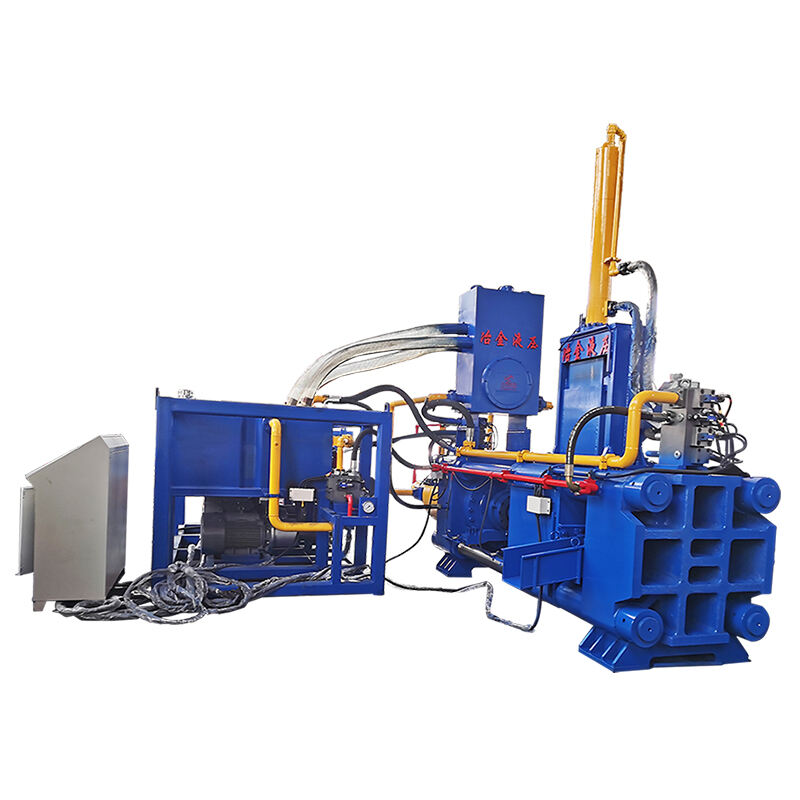

A Steel Turnings Briquetting Press is a type of briquette machine, that generates low pressure through a mechanism (crank) to lift up the piston and compress the different materials into one cube or block. There are kinds of Briquetting machines, including wood briquette press and straw bale crusher. Some Other Examples of Model Types in Briquetting Presses:

At steel turnings briquetting press, customer satisfaction is our main goal. We offer flexible and customized solutions to meet the specific needs of our clients. Our after-sales staff is ready to help, whether you have any questions regarding the operation of the equipment or require assistance in troubleshooting. From purchase to installation, we are dedicated to providing a seamless and efficient service to our customers.

Two of our state-of-the-art facilities with a total area of 30 000 square meters and are outfitted with the latest technology and staffed by a dedicated team of over steel turnings briquetting press professionals comprising 17 experts We are proud of our outstanding capabilities in research and development evidenced by the 12 national patents we have Our passion for innovation allows us to consistently provide high-quality and efficient hydraulic equipment

We offer a variety of hydraulic equipment including hydraulic pressing presses for briquetting steel turnings briquetting press and hydraulic alligator shears Our products are designed for many different applications across various industries including steel mills foundries the automotive industry construction energy generation and scrap recycling of metal This flexibility makes our equipment an ideal fit for a variety of industrial needs

The company was established in 1989 Jiangyin Metallurgy Hydraulic Machinery Factory has more than steel turnings briquetting press years' experience in the field of hydraulic machinery We are well known in the scrap metal recycling business for our long-standing experience and continuous expansion We have successfully expanded our presence in more than 30 countries that include Russia Brazil and Japan that demonstrates our strength and reliability in the field

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy