Sheet metal shears are some of the most useful tools used for cutting metal to different shapes. You can work with them in a lot of projects, and they can be incredibly useful. Key to achieving good results is to know how to use them properly. This guide will discuss everything you need to know about sheet metal cutters — the basics, tips and tricks for using them, why they are important for your project, the varieties available and how to maintain them.

Sheet metal shears are specialty hand tools designed to make cutting through large pieces of sheet metal a breeze. They feature sharp blades that close up to cut the metal. There are several types of shears; manual shears, operated via hand pressure, electric shears, which operate from electrical power. " You'll want to be sure to use these sheet metal shears with safety in mind to avoid accidents.

When using a sheet metal shear, ensure the metal is secure before you start cutting. This makes it easy to get clean, straight cuts. And, as always, don safety gear, such as gloves and goggles, to keep sharp edges or flying metal fragments at bay. Slow and steady cuts make the best cuts, move the shear slowly and steadily.

Sheet metal shears are important because they allow you to cut metal sheets into various forms. This is really crucial for projects requiring precision measurements. When done without a sheet metal shear, cutting metal sheets to fit is a laborious, difficult process, and one that could compromise the quality of your project. It’s an improvement for you, and allows you to get more done, and do it right.

Sheet Metal Shears There are a number of different types of sheet metal shears available with a range of capabilities. Hand shears are fantastic for little jobs or for the aficionado who prefers to work manually. Electric shears are better for more extensive projects or when you have a lot of cuts to make at once. Picking the right shear is critical to getting the best results from your project.

Here is how you can do your part to keep your sheet metal shear in tip top clinical condition. This helps prevent rust, keeps the blades sharp. Keep your shear dry to prevent rust and rot. If you notice any issues with your shear, repair them immediately to prevent additional damage.

At Jiangyin Metallurgy Hydraulic Machinery Factory, customer satisfaction is our first priority. We offer flexible and sheet metal shear that satisfy our customers particular requirements. Our support staff is on hand to assist, whether you have any questions regarding the operation of the equipment or require assistance with troubleshooting. We're dedicated to providing the smoothest and most efficient experience for our customers from purchase to installation and beyond.

In 1989 Jiangyin Metallurgy Hydraulic Machinery Factory has more than 30 years' experience in the field of hydraulic machinery We are well known in the recycling of scrap metal for the depth of our experience and steady growth We have been able to sheet metal shear our market presence to more than 30 countries which includes Russia Brazil and Japan that demonstrates our strength and reliability in the industry

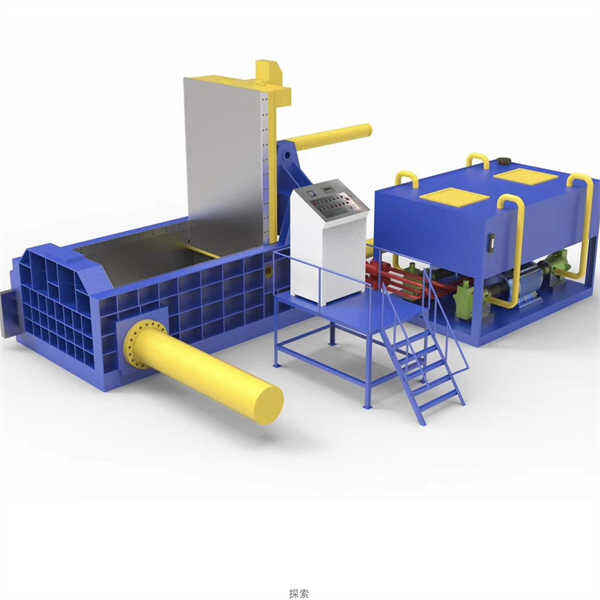

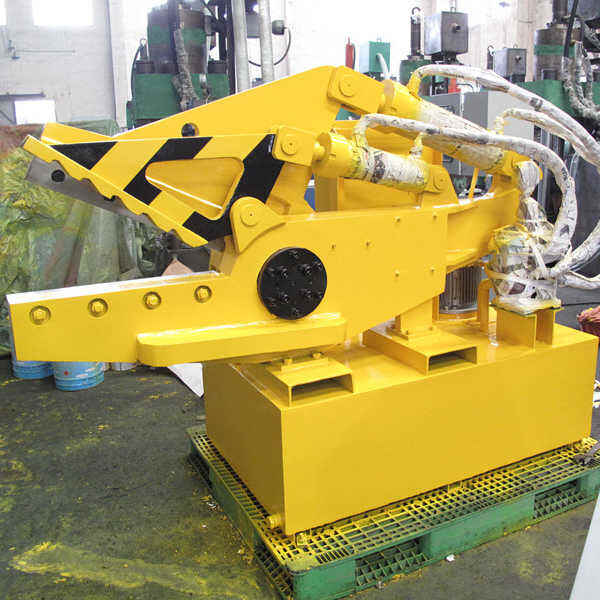

sheet metal shear have a broad range of hydraulic equipment such as hydraulic briquetting press and hydraulic metal balers as well as hydraulic alligators shears Our products are designed to work in diverse applications across different industries such as steel mills foundries construction the automotive sector energy generation scrap metal recycling Our equipment is perfect for numerous industrial applications because of its versatility

Our two state-of-the-art plants that span sheet metal shear are equipped with cutting-edge technology and are staffed by a committed team of more than 150 professionals comprising 17 experts We pride ourselves on our outstanding capabilities in research and development evidenced by the 12 national patents we hold Our commitment to innovation guarantees that we always provide high-quality and effective hydraulic machinery solutions

Copyright © Jiangyin Metallurgy Hydraulic Machinery Factory All Rights Reserved | Blog | Privacy Policy